Buy and Download this COMPLETE Service and Repair Manual. It covers every single repair and service procedure detail on your Caterpillar 216 Skid Steer Loader, Caterpillar 226 Skid Steer Loader, and Caterpillar 228 Skid Steer Loader.

This is the authentic factory service manual from Caterpillar which covers every repair and service procedure. Factory Service and Repair Manual For Caterpillar 216, 226, 228 Skid Steer Loader Powered by 3034 Engine.

The Cat® 259D3 Compact Track Loader, with its vertical lift design, delivers extended reach and lift height for quick and easy truck loading. Its standard, suspended undercarriage system provides superior traction, flotation, stability and speed to work in a wide range of applications and underfoot conditions. Download the D Series Skid Steer Loader, Compact Track Loader and Multi Terrain Loader Parts Reference Guide to access part numbers for first 3,000 hours of operation. Attachment Options Cat Skid Steer Loader and Compact Track Loader attachment options let you get more out of your machines. This Caterpillar 279C, 279C2, 289C, 289C2, 299C Compact Track Loaders service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting) is divided into different sections. Each section covers a specific component or system with detailed illustrations. † The Service Manual and Parts Manual are available from your dealer for use by mechanics to do shop-type service and repair work. † The Skid-Steer Loader Operator Training Course is available through your local dealer or at www.training.bobcat.com or www.bobcat.com. This course is intended to provide rules and practices. We offer brand new OEM Caterpillar Shop Service Manuals on all Caterpillar Engines, Cat Skid Steer Loaders (SSL), Caterpillar Backhoe Loaders (BHL), Cat Excavators, Caterpillar Track Type Tractors (TTT-Bulldozers), Caterpillar Track Type Loaders (TTL), Cat Multi-Terrain Loaders (MTL), Caterpillar Wheel Loaders, Cat Motor Graders, Caterpillar.

Step by step instructions, illustrations, diagrams, Testing and Adjusting, Disassembly and Assembly, Remove and Install, Specifications, Operations, Schematic and much more for Caterpillar service and repair.

Engine:- 3034 Engine

Years:- All years included

Filesize:- 285 MB

MODELS

CAT 216 Skid Steer Loader 4NZ00001-03399 (MACHINE) POWERED BY

3034 Engine

CAT 226 Skid Steer Loader 5FZ00001-06699 (MACHINE) POWERED BY

3034 Engine

CAT 228 Skid Steer Loader 6BZ00001-00699 (MACHINE) POWERED BY

3034 Engine

Model Year: All

LANGUAGE: English

FORMAT: PDF 3765 pages searchable

ZOOM IN/OUT: YES Instant Download: YES

COMPATIBLE: All Versions of Windows & Mac

This is not generic repair information! It is vehicle specific. This is the exact same manual used by technicians at the dealership to maintain, service, diagnose and repair your Caterpillar.

Complete step-by-step instructions, diagrams, illustrations, wiring schematics, and specifications to completely repair your Caterpillar with ease!

You get everything you will ever need in one easy-to-use PDF manual. No more flipping through books to find what you need. Print only the pages and diagrams you require. No more greasy pages or torn/lost paper manuals again.

All pages are printable, so print off what you need and take it with you to your vehicle or workshop. You can blow-up images and then print off enlarged copies!

This is the factory specific, highly detailed repair manual, with complete instructions and illustrations, wiring schematics and diagrams to completely service and repair your Caterpillar.

All Manuals Are Windows and Mac compatible!

YOU WILL BE GIVEN THE DOWNLOAD IMMEDIATELY UPON RECEIPT OF YOUR PAYMENT.. NO WAITING!

FIND IT…PRINT IT…USE IT…then Trash it.

Tons of pictures and diagrams at your fingertips!!

Save Money $$ By doing your own repairs! These manuals make it easy for any skill level WITH THESE VERY EASY TO FOLLOW, STEP-BY-STEP INSTRUCTIONS!

INSTANT DOWNLOAD means NO SHIPPING COST or WAITING FOR A BOOK OR CD TO ARRIVE IN THE MAIL…YOU WILL RECEIVE THIS MANUAL TODAY VIA DOWNLOAD ON COMPLETION OF PAYMENT VIA OUR SECURE PAYMENT PROCESSOR. WE ACCEPT ALL MAJOR CREDIT/DEBIT CARDS

INSTANT DOWNLOAD (add to cart)

Caterpillar 239D and 249D Compact Track Loaders and 226D and 232D Skid Steer Loaders Factory Service & Shop Manual

Complete workshop & service manual with electrical wiring diagrams for Caterpillar 239D and 249D Compact Track Loaders and 226D and 232D Skid Steer Loaders. It’s the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

Caterpillar 239D and 249D Compact Track Loaders and 226D and 232D Skid Steer Loaders service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

5,35 pages, bookmarked, Searchable, Printable, high quality PDF

UENR4243 – Disassembly and Assembly (239D and 249D Compact Track Loaders and 226D and 232D Skid Steer Loaders Engine Supplement)

UENR4244 – Specifications (239D and 249D Compact Track Loaders and 226D and 232D Skid Steer Loaders)

UENR4244 – Systems Operation (239D and 249D Compact Track Loaders and 226D and 232D Skid Steer Loaders)

UENR4244 – Testing and Adjusting (239D and 249D Compact Track Loaders and 226D and 232D Skid Steer Loaders)

UENR4245 – Disassembly and Assembly (239D and 249D Compact Track Loaders and 226D and 232D Skid Steer Loaders Machine Systems)

UENR4246 – Disassembly and Assembly (239D and 249D Compact Track Loaders and 226D and 232D Skid Steer Loaders Powertrain)

UENR6683 – Schematic (226D and 232D Skid Steer Loader 239D and 249D Compact Track Loader Hydraulic System).pdf

UENR6684 – Schematic (226D and 232D Skid Steer Loader 239D and 249D Compact Track Loader Electrical System)

UENR6685 – Schematic (226D and 232D Skid Steer Loader 239D and 249D Compact Track Loader Electrical System).pdf

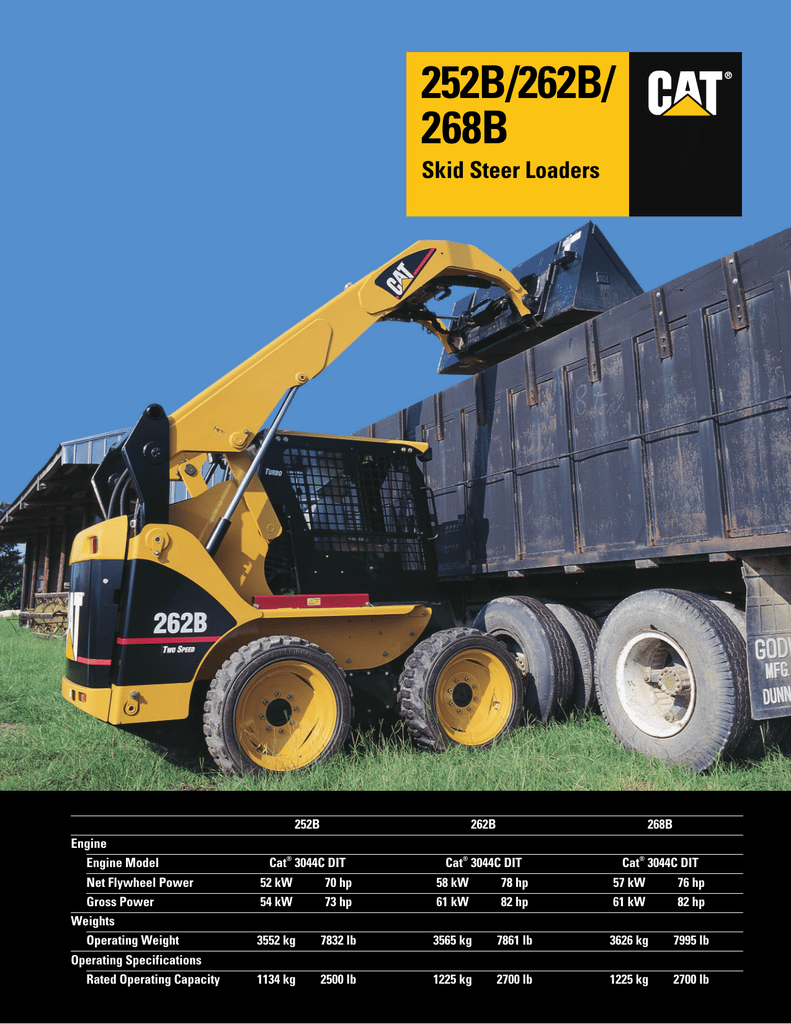

252b Cat Skid Steer Manual

EXCERPT:

Because the rotor is connected to the shaft (7) by splines, the rotor turns the shaft. As the rotor turns, the previously exposed ports are covered and the previously covered ports are exposed. The fully extended piston assembly next passes over an exposed port.

As the piston rollers follow the inner diameter of the rotor housing, the rollers force the piston assembly toward the shaft (7). The hydraulic oil that is in the cavity is forced through the exposed port by the inward motion of the piston assembly. The hydraulic oil then returns to an annular passage. The oil then flows out of the port (13). This oil is the low-pressure loop.

The port (14) provides a case drain for the oil that leaks past the piston assemblies and from the flushing valve (6). The flushing valve is a shuttle type valve that provides a means for the oil to flow to the hydraulic oil cooler. The cooled oil will cool the motor. The flushing valve also provides a means to flush harmful

particles from the motor.

The oil that flows through the flushing valve flows from the low-pressure side of the drive loop. When the oil pressure in the annular passage increases, the oil pressure acts against the spool for flushing valve (6). The oil pressure overcomes the force of the spring . The oil pressure forces the spool to shift. When the spool shifts the spool opens a path to the return manifold for the oil that is in the annular passage.

…